Sustainable journey: the urgency of zero-emission temperature controlled trailers

Keeping products at the right temperature is increasingly important. The current diesel-powered solution is not meeting the sustainability goals we aspire to in the mobility sector. That is why TIP is actively looking into electrical Trailer Refrigeration Units (TRU) that can operate with zero emission.

Global warming calls for industry change

The European Union calls upon major industries to invest in sustainable solutions. For logistic services this means we strive to cut carbon emissions to reverse the effect of climate change.

Scientists agree that a rise in temperature is inevitable, even if we reach our goals. ‘The coldest summer of the rest of our lives’, society has started calling it. An increasingly hot climate means a growing dependency on good refrigeration. For medicine and food especially since these products are gaining in value because of the more intense weather, growing population and more global health challenges.

Temperature Controlled trailers in transportations will need to be relied on even more in the future. The current TRUs are keeping the products at the right temperature and are meeting our requirements. But these high-performance engines are still fuelled by diesel, ironically adding to the problem it will be asked to solve in the future. It does not make sense to retain the status quo where an engine that is asked to keep valuable customer goods cooled, adds to global warming.

It is remarkable that the EU has set very strict limits on the diesel powered truck-engine but has not (yet) regulated the emissions of the reefers in the trailers. It is TIP’s goal to stay ahead of these possible restrictions and integrate innovation on time.

Electrify the on-board Temperature Control

If the mobility sector is gradually electrifying its engines, why stop at the propulsion of the vehicle? The TRU can be made electric and operate on the onboard power supply. The benefits of such a sustainable innovation would contribute to emission reduction goals and cleaner, quieter cities but also reduce dependency on facilities and costs for fuel on-board.

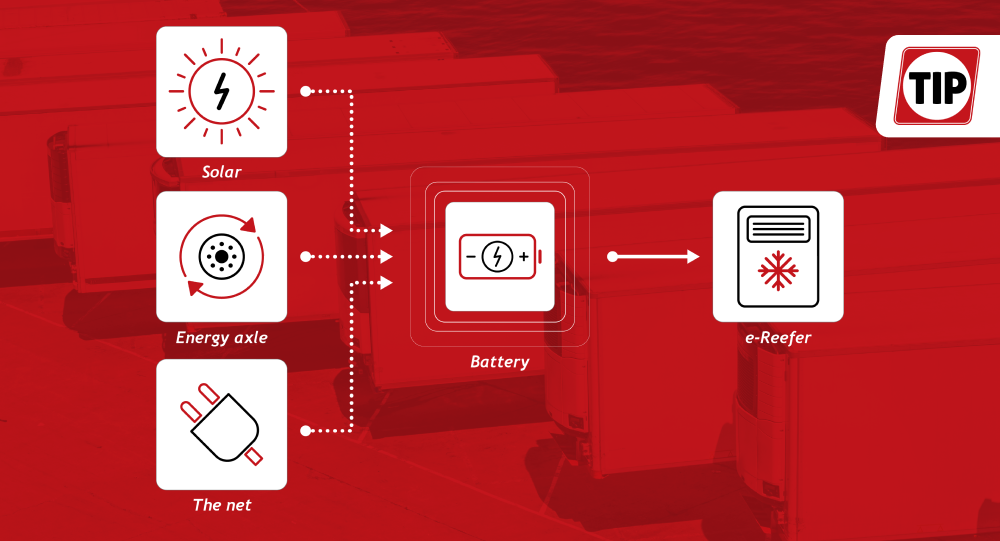

The core element of the redesign of a Temperature Controlled trailer is to electrify the TRU. To supply the engine with sufficient power, an advanced battery system should be mounted to the trailer. Thirdly, an efficient way to charge that battery is needed to make the concept reliable and viable.

The eTRU, an accessible alternative with a battery designed to perform for the entire duration of the journey

The core of the solution is electrifying the TRU and its engine. These are currently already available and go by the name ‘eTRU’. Using electricity powered fans and cooling/heating systems, the first models that TIP put on trial in 2022 have a modified Thermo King engine (Advancer A400) in combination with a battery pack from Maxwell+Spark (70 kWh) that can keep the freight chilled at temperatures down to -25°C (source: TIP Group).

The light-weight specialised battery system from Maxwell+Spark with its 70 kilowatt-hours (kWh) can run the TRU completely on electricity during working hours and is optimal and has to have a sufficient output for the duration of the transport. Additionally, it has the margin to stand still without being able to charge on the net. A lot of innovation is still happening in this sector to make it more efficient.

Charged on the net

It is common that the batteries are charged via a cable and a three-phase power connection to the grid. For the logistics sector, this could happen during loading and unloading of freight or when drivers are on a break. At this moment, using only a high capacity battery pack is more cost-effective and can be retro-fitted into our existing trailers. However, there are possibilities to charge power on-board that can be explored:

- Additional charge with an energy axle

Currently in cold chain services, trailers can generate their own electricity with kinetic energy with a special axle. Using a generator, the fridge can run while the vehicle is in motion and can charge in-built batteries that allow the trailer to be cooled or heated while stationary for up to 90 minutes. This ensures a renewable source and zero-emissions but also reduces reliability of charging-facilities and lowers costs.

- Charged with solar panels

Solar panels would have the same benefits but use another source of energy income, namely solar power. It is a more popular solution that has yet to be proven in the trailer industry.

The first step to sustainable change

In the Netherlands, TIP’s first trial of several months has successfully been rounded up in July 2022. Two trailer units ran completely electric to safely transport ice creams for Unilever across the Dutch roads. This way of temperature-controlled transport kept freight chilled down to -25°C by using only green energy. Each unit saves up to 25 tons of CO2 per year, contributing to the lowering of emissions in the transportation sector. Overall benefits of this improvement would be a cleaner and more efficient trailer solution.

Next steps to reach sustainable goals

After the success of the first trial, TIP and Unilever looked at the results and assessed what was needed to make future units even better. Now, in the summer of 2022, they in total have four trailers in use on the hot summer roads of the Netherlands. The roadmap is optimistic: once these trailers have proven their abilities, the technology can be rolled out across a larger fleet. Eventually, TIP hopes to inspire a wider sector to collaborate so they can improve on making a sustainable impact and remaining competitive.

Let’s innovate now!

It has become clear for the logistics sector that the Temperature Controlled distribution network needs to innovate towards trustworthy zero-emission solutions. Relying on outdated diesel engines is no longer viable. Current battery-based solutions show promising results, but there is definitely still much to gain in the on-board generation of power to become more independent and secure energy-efficiency.

It is an exciting proposition to electrify the cold chain for many parties, from shipper to carrier and equipment provider, lowering costs while making improvements that improve living quality and fight climate change on a large scale.

For more information on TIP’s innovation, please take a look at the news section of our website or reach out to your TIP contact!