Low-emission Temperature Controlled transportation

A new way of powering the reefer engine can make temperature control in trailers carbon free

The challenge in Temperature Controlled transportation

Hundreds of leading scientists agreed that since 2010 the greenhouse gas emissions emitted because of human activity have only increased. “We are at a crossroads,” IPCC Chair Hoesung Lee said, “the decisions we make now can secure a liveable future”. Governments and all major industries globally are called upon to innovate and curb emission. In highly populated cities, regulation is in place to avoid air pollution, not only for the environment but also for the safety and quality of life for the people living in the city. For the mobility sector, this means we have to invest in more sustainable transportation solutions. One generally adopted approach is the electrification of engines since there is no gas emission while driving and the battery can be charged with renewable energy. The summer of 2021 has been referred to as the “coldest summer of the rest of our lives”. Although there are fluctuations in the rise in temperature, it is certain that the larger trend is that our earth is bound for an intensified global warming over the next 30 years. According to the most recent UN climate report, it is unavoidable that in the future, we are going to have to cope with higher temperatures. Currently, trailers for the transportation of customer goods are already highly insulated and equipped with cooling engines that keep products at the right temperature to ensure the security and quality.

“The current systems run outdated and inefficient diesel engines, because they are not subjected to on-road emission standards. These car-engine sized - but not car-engine efficient - diesel engines are used for up to ten hours per day. That is ten times the average time a car is on the road for! All this creates massive pollution, but also costs more and more in fuel.”

Clinton Bemont, CEO at Maxwell and Spark

This same climate crisis, in combination with growing inequality, conflicts and the recent pandemic have undermined global food security world-wide. 1 in 10 people are suffering from hunger, and half of the countries are affected by soaring food prices. This makes food a more scarce and therefore a more valuable commodity. The UN Environment Programme reports that “as much as half of some temperature-sensitive produce is lost post-harvest primarily because of lack of or inadequate access to cold-chain logistics”. Good refrigeration from harvest to consumer could drastically reduce food waste. In addition, temperature sensitive health care products are also in need of an unbroken cold chain. We can conclude that keeping valuable goods at the right temperature during transport will be more crucial in the future. Good Temperature Controlled trailers in transportations will need to be relied on even more in the future. The current TRU’s are keeping the products at the right temperature and are meeting our requirements. But these high-performance engines are still fuelled by diesel, ironically adding to the problem it will be asked to solve in the future. It does not make sense to retain the status quo where an engine that is asked to keep valuable customer goods at the right temperature, adds to global warming. It is remarkable that the EU has set very strict limits on the diesel powered truck-engine but has not (yet) regulated the emissions of the TRUs in the trailers. Whereas it is estimated that keeping food cold accounts for an estimated 20% of total vehicles’ fuel. It is the industry’s challenge to stay ahead of these possible restrictions and integrate innovation on time. If the mobility sector is gradually electrifying its engines, why stop at the propulsion of the vehicle? The TRU can be made electric and operate on the onboard power supply. The benefits of such a sustainable innovation would contribute to emission reduction goals and cleaner cities. In this white-paper, the design of such a solution is proposed and the current test-results are set out.

Our battery-based solution

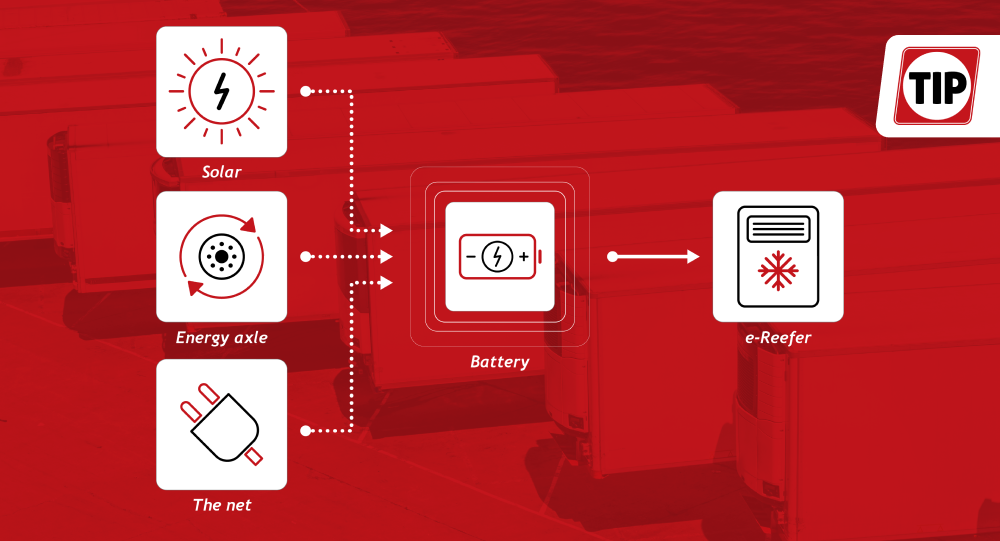

The core element of the redesign of a Temperature Controlled trailer is to electrify the TRU. To supply the engine with sufficient power, an advanced battery system should be mounted to the trailer. Thirdly, an efficient way to charge that battery is needed to make the concept reliable and viable.

Electric TRU

Most importantly, the TRU should be electrical. These are currently already available and go by the name “eTRU”. Using electricity powered fans and temperature control systems, they can keep the freight chilled at temperatures down to -25°C. Up until now, the performance is promising and would pose no risk for this innovation to scale. Time will tell whether the lifecycle of these TRUs are equal to the dieselpowered one, with low malfunction. Based on similar electrification of engines, one could hypothesise that these e-TRUs degrade slower resulting in less maintenance resulting and eventually lower costs. For this innovation to be a real improvement, it is crucial that the electrical engine is highly efficient (using minimal electricity for quality cooling) and utterly reliable (showing low malfunction). To ensure rapid adoption in the transportation sector, the guarantee of low costs, for investment and integration as well as maintenance is important.

Battery system

A lot of innovation is happening in the batterysector, improving the products available by the month. For this design, a light-weight solution is optimal and has to have a sufficient output for the duration of the transport and margin to stand still without being able to charge on the net. There are two ways of charging the batteries that can be used on a cold chain trailer. The first one is to charge the battery on the power supply network by plugging it into an outlet. A second option would be to generate power on-board of the vehicle, from which we explore the renewable possibilities: kinetic and solar energy. Currently, charging the battery on the net is a more cost-effective solution that is easier to integrate in the trailers. However, we believe that the addition of on-board power generation could have benefits for the long term: reducing dependency on the grid and guaranteeing greener solutions. It is part of the logistic chain puzzle to discover which direction is worth exploring for which fleet.

Charging the battery on the net

In the mobility sector, mainly in privatised vehicles, it is common that the batteries are charged via a cable and a three-phase power connection to the grid. It would require minimal effort to install such sockets and the plugs are also available for the industry since the innovation in this sector has already proven itself. Some investment is still needed to place the required outlets at the right places. Using an analysis of current logistics, the optimal points could be assigned and the transition can be guided accurately. Likely charging stations would be where the trailer is inactive, like the loading place and the unloading place. Drivers also need to recharge, making their common resting places great hubs for charging. The charging of the battery by plugging it in will need a major behavioural change of the drivers, otherwise the concept is not reliable. It has to become a habit to manually connect the battery to the net when possible or required. During the transition to electrical TRUs that are charged on the net, this could be a liability. Additional guidance and ease of usage are key to make the new system reliable and fast. The higher the battery capacity, the more expensive the system becomes. Therefore, the challenge is to minimise the needed capacity without losing any reliability. A solution at hand would be to generate electricity while driving on the trailer. This way the reliability of a system with lower capacity batteries is increased, additionally renewable energy sources could also ensure a zero-emission generation of electricity. At this moment, using only a high capacity battery pack is more cost-effective and can be retro-fitted into our existing trailers. We explore the options of an energy axle and solar panels in this white-paper.

Charging with an energy axle

Currently in cold chain services, trailers can generate their own electricity with kinetic energy from the wheels or when breaking. This way of gaining electricity has been in use in the US for over three years, providing McDonalds with power for tail lifts and pallet trucks and shows promising advantages for Temperature Controlled trailers. Using a generator, the fridge can run while the vehicle is in motion and can charge in-built batteries that allow the trailer to be cooled while stationary for up to 90 minutes. The benefits of such a solution would be that the carrier is less reliable on the grid and has a guaranteed greener outcome. In combination with a battery-pack, this does not only contribute to goals set to reach zero-emission to mitigate climate change and provide healthier living environments for citizens, it also means that the carrier is less reliable on infrastructure so more flexible and a significant cost reduction in cooling the produce.

Charging with solar panels

A less proven concept in the mobility sector is using solar panels to charge the battery. There are concepts that show great potential for cars to use the power of the sun to run charge a battery system that runs an engine. These panels could be installed on top - or even at the sides - of a trailer and generate electricity. Similar to the energy axle, the solar panels could feed power to the batteries to keep the refrigeration running for longer. According to Sono Motors, a solar integration will provide the refrigeration unit on the trailer with an additional 9.8kW, which can offer fuel savings and reduce carbon emissions.

“A road trial proved the sunpowered Transportation Refrigeration Unit is a viable replacement for diesel TRUs: it meets the most challenging route requirements, it saves significantly on TCO and it supports a netzero strategy. We support any innovation that can support the industry with decarbonisation.”

Alastair Gough, Head of Business Development at Sunswap

Mounting

In newly produced models of Temperature Controlled trailers, the electric system can be integrated in the design from the beginning. Fully embedding the components and electrical wiring is the most secure way of mounting a TRU, batteries, a charging unit and possible additional on-board power solutions. This would guarantee safety of use and would be engineered to be the most durable design. Optionally, the TRU, battery system and charging solution can be modified in such a way that it can be mounted on current trailers. With this so-called retro-fit, carriers need to make a relatively low investment to electrify their Temperature Controlled transport and we avoid the premature depreciation of Temperature Controlled trailers. The components would be attached to the trailer with clamps and spotwelding on the safest and most reliable spots. Electrical wiring will be incorporated neatly where necessary. A possible configuration of the complete system is shown in Figure 1:

Figure 1: proposed system of low-emission cooled trailers

Promising results

In the Netherlands, the first Proof of Concept (PoC) of several months has successfully been rounded up in July 2022. Two trailer units ran completely electric to safely transport Ben & Jerry © Ice Cream across the warm Dutch summer roads. In this current tests, a modified Thermo King TRU is used together with a lithium-ion battery with high energy density from Maxwell+Spark. They have investigated and continuously developed batteries for transport refrigeration power since 2016, originally in Africa. Now, a special design for the Thermo King TRU engine was made for the current tests in Europe. This way of temperature-controlled transport can keep freight chilled down to -25°C by using only green energy. Each unit could save up to 25 tons of CO2 per year, contributing to the lowering of emissions in the transportation sector. Overall benefits would be a cleaner and more efficient trailer solution.

What’s next?

Because of the success of the first tests, two more trailers are engineered to test in the summer of 2022 by TIP and Unilever. The hypothesis of the first test is extended: not only a great reduction in greenhouse gas emissions and equal or more reliability to the current diesel-powered solution. But also provide an economic benefit of reduced costs for fuel and reduce noise disturbance significantly. More research and development has to be done to engineer and integrate the e-TRU and battery seamlessly and ensure the most efficient and safe solution. Further possible integrations, like the energy axle and solarpanels should be put in trial for specific purposes in the right context. Putting these solutions into work and monitoring them closely for multiple iterations will allow for a secure and rapid adoption of battery-based solutions in the cold chain by carriers around the world.

“TIP has seen its customers increasingly look to adopt cleaner and more efficient trailer solutions. We support innovative solutions that drive the industry to be more sustainable so replacing diesel-powered TRU with electric TRU is progress we believe in. That is why we invest in it, test it and get the Proof of Concept. We do not make things, but we do make things happen”

Rogier Laan, VP global sales and marketing at TIP

“With logistics and distribution accounting for around 15% of our emissions, we are moving our cold chain to cleaner sources of energy. We are partnering with innovators to pioneer new technology and find new solutions. This journey of co-creation will provide us with valuable learnings and insights to help us lower emissions from our vehicle fleet.” Michelle Grose, Head of Logistics and Fulfilment at Unilever

Conclusion

It became clear for the logistics sector that the cold chain distribution network needs to innovate towards trustworthy zero-emission solutions. Relying on outdated diesel engines is no longer viable, because of its (relatively undiscussed) contribution to global warming, noise disturbance and rising costs. To remain ahead of legal restrictions that push for fast and unthoughtful changes but also the internal motivation of the transportation sector to move towards zero-emission, this paper opts to invest in the electrical possibilities at hand and explore these in different contexts and settings with all stakeholders. Research is promising, showing the environmental benefits of electrification. Current batterybased solutions exceed expectations, but there is definitely still much to gain in the on-board generation of power to become more independent and secure energy-efficiency. It is an exciting proposition to electrify Temperature Controlled chain for many parties, from shipper to carrier to equipment provider, lowering costs while making improvements that improve life quality for citizens and most importantly: fight climate change on a large scale.